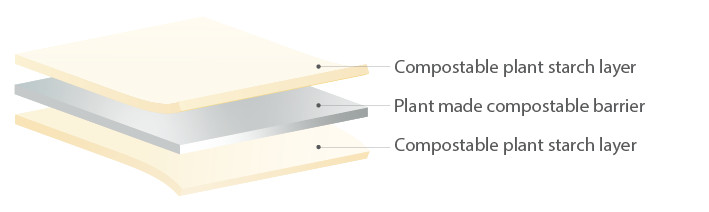

Compostable PLA laminate with MPLA barrier

This laminate is completely compostable and can be printed in intricate designs. It has a high barrier to oxygen and moisture and protects the content well.

Considerations

- Given that it’s made from non-fossil fuels, the carbon footprint of this material is relatively low.

- It has a very good printability, as the outer PLA material is transparent and has a good ink adhesion.

- Completely compostable in industrial composting facilities.

- Good barrier protection.

- The increased use of compostable materials will create the demand for composting infrastructure to be built, this is already happening across several jurisdictions.

Frequently asked questions

Industrial composting takes place as an industrial plant, where temperature, moisture and soil bacteria levels are tightly controlled. If you home compost, you will have much less control of the process, and people in say Northern Sweden will not be able to compost at all for large parts of the year. Many suppliers offer home compostable materials, however this means that barrier properties and add-ons such as valves for coffee are compromised away. At the same time, people only rarely home compost, for instance only 3% of British households home compost.

We have therefore chosen to focus on industrial composting, so a compostable bag should be disposed of in the food waste recycling stream.

Compostable materials are designed to be composted and not recycled, so they are unfortunately not recyclable in the plastic waste stream. Even though commercial composting is only available kerbside in some jurisdictions, this is changing rapidly.

All our compostable materials are certified compostable, so they have been tested for biodegradation. They do not leave micro-plastics behind.

Dispose of in the food waste recycling stream where this exists.

All the materials out laminates are made for are as a minimum certified EN13432 industrially compostable.

EN13432 is the EU standard for compostability. Products certified under this standard must meet stringent requirements for biodegradability, understood as the capability of the packaging material to be metabolically converted into carbon dioxide; disintegradability, understood as fragmentation and loss of visibility in the final compost (absence of visual pollution); and Absence of negative effects on the final compost, meaning that the compost should be good for growing food in.

Our recyclable materials should be disposed of in a soft plastics or Resin identification code 4 waste stream. Currently, Tesco and COOP offers this in the UK, RedCycle offers this in Australia, and there are similar schemes worldwide.

Unfortunately, not yet, as most recycled plastics are not legal to use for food use. This is due to use contamination, which existing mechanical recycling methods cannot remove properly. This is changing rapidly, as the EU is issuing guidelines for how to recycle back to food safe standard, while recently opened chemical recycling plants can recycle any post consumer use plastic back to virgin plastic standard.

This requires a complex answer. They do not contain what most understand as plastics, however PLA, Bi-PBS, NKME are all per definition plastics, even though they are generated from non-fossil sources. They are however compostable and degrade into CO2 and water only, not leaving any micro-plastics behind.

EN13432 requires the compostable plastic to disintegrate within 12 weeks and completely degrade within 6 months. This means that at least 90% of the plastic material will be converted into CO2 within this period. The last up to 10% will have been converted into water and valuable compost.

Industrially compostable materials will only degrade under certain conditions, such as those found in an industrial compost heap. In nearly all other situations the materials will not degrade.